We are capable of machining a wide range of materials which is best suited as per customers’ application and requirement.

Few commonly used metals and thermoplastics includes.

- ● Brass : Lead Free Brass, Free Cutting Brass, Naval Brass, Leaded Brass & Red Brass

- ● Bronze: Aluminium Bronze, Nickel Bronze, Silicon Bronze, Manganese Bronze, Tin Bronze, Leaded Bronze, Low Leaded Bronze, Non Leaded Bronze & Bismuth Bronze.

- ● Sand Casting: Sand casting also known as sand molded casting, is a metal casting process characterized by using sand as the mold material.

- ● Shell Molding: Shell moulding also known as shell-mould casting, is an expendable mold casting process that uses a resin covered sand to form the mold.

- ● Product Designing Aid for Components' Cost Efficiency

- ● Iron Casting: Cast iron is a group of iron-carbon alloys with a carbon content greater than 2%. Its usefulness derives from its relatively low melting temperature.

- ● Investment Casting: Investment casting is an industrial process based on lost-wax casting, one of the oldest known metal-forming techniques.

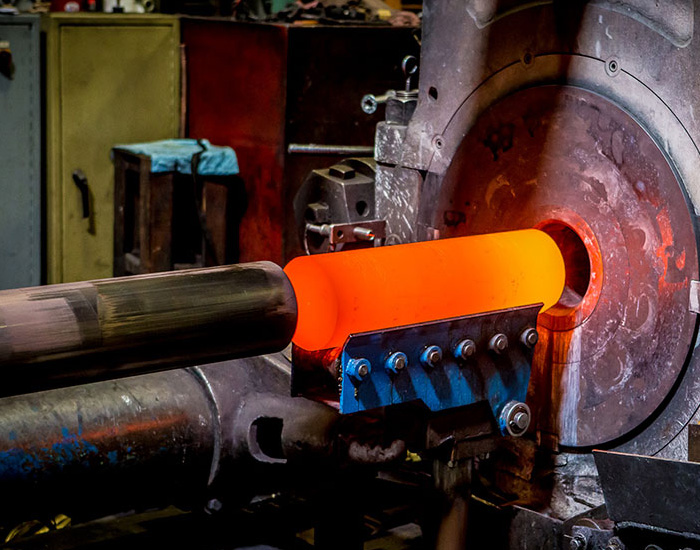

- ● Forging: Forging is a manufacturing process involving the shaping of metal using localized compressive forces.